Technical data

Work area

- The NHS NewAge Tx series spans 4 variants, equipped with 2 to 5 tines.

- The tines can be adjusted from 40 to 65cm actual working depth, but with an impact depth as low as 100cm.

- The width impact of the tines is between 70 - 90cm per tine, giving a maximum working width of 430cm (NHS NewAge T5)

The tines

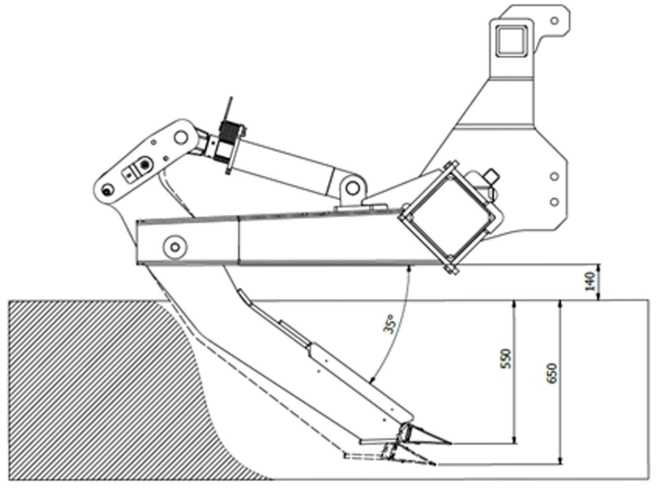

- The optimal setting angle of the tine is 35°.

- The optimal, real melioration depth for most soils is: 55cm.

- Each individual tine is equipped with a spring bolt that is released and thus protects the meliorator and tractor when hitting larger objects such as large stones, hidden under the surface.

- Each individual tine is equipped with replaceable wear parts that ensure a long service life for the tine and optimal yield from the melioration.

Flexible setting

- Each tine can be individually adjusted in width on all models. This allows, among other things, for improving tramlines, adapted to different track widths.

- Each tine can be individually engaged or disengaged. This in the case, for example, of particularly high power requirements or when improving tramlines on sown areas with machines with 3 or more tine.

Optimal weight transfer

-

The design, with a center of gravity closest to the three-point linkage, accommodates weight transfer to the tractor to such an extent that the Meliorator requires less traction than would be immediately expected.

-

For NHS NewAge T2, tractors from 75kW and up are therefore recommended.

Working depth:

- Setting options: 40-65 cm.

- Optimal Real melioration depth: 55 cm.

- Impact depth down to 1000 mm

Wear/ spare parts:

- Tip

- Leading edge

- Shearbolt (stone release mechanism)

Working position:

- Hydraulic unfolding

- Working position always against fixed stop

- Working position depending on the linkage setting on the tractor

- Each tine can be individually disengaged as needed

Mechanical stone release

Function:

If a tine hits a larger object (e.g. boulder), a safety bolt in the tine mount is cut

and the tine is forced backwards and away from its normal, ground-seeking working position.

The machine is lifted off the ground if the safety bolt breaks.

Adjustment:

The mount for the safety bolt is replaceable and the breaking strength can be adjusted for larger or smaller diameters of the bolt.

A broken bolt is replaced by forcing the tine back into working position, whereby a new bolt can be mounted.

Adjusting working depth

The tine:

Mechanical intermediate plates are mounted on the hydraulic cylinder, which increase or limit the cylinder's stroke length when engaged and disengaged. In this way, the tine can be adjusted, but still maintain a fixed stop against the working position. The cylinder itself is set at the factory so that all tine tips always have exactly the same position in the working position.

Machine/tractor:

The working depth can be adjusted using the tractor's lift. As long as the machine's 3-point suspension is vertical, the working depth is changed without affecting the tine angle. If an increased working depth is desired (by adjusting the tine), the top link is subsequently extended, thereby maintaining the tine angle.